As biotech and pharma companies race to bring innovative new therapies to market, they face immense manufacturing hurdles that can derail development. In this insightful editorial from Scrip (subscription required), industry thought leaders offers actionable recommendations to overcome key production challenges.

Our own Anshul Mangal—leveraging his own decade plus of experience leading manufacturing for cell and gene therapy pioneers—provides unique insights on the manufacturing paradigm shifts required to deliver on the vast potential of emerging modalities.

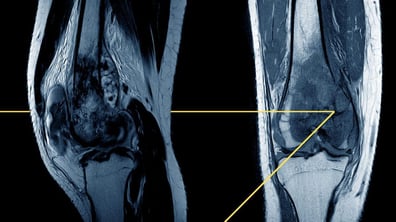

"There are several exciting technologies and modalities that have the potential to disrupt biopharma in 2024 and beyond. Cell and gene therapies will continue to dominate the innovative clinical pipeline with the largest number of treatments in clinical trials (589 gene therapies and 568 cell therapies). The recent historic landmark of the first CRISPR technology gaining regulatory approval signals confidence in this approach.

Additionally, as the adoption of radioligand therapy increases, it continues to show profound potential, one of the most promising aspects of radio ligand therapy lies in the potential to create unique combinations of radioactive atoms and targeting molecules tailored to specific tumor types. While the current indication list is limited, industry pioneers are boldly experimenting with these interchangeable building blocks, envisioning therapies capable of addressing a diverse spectrum of cancers and diseases. These strategies are vital for achieving long-term success in delivering innovative therapeutics to patients at scale."

Anshul MangalPresident, Project Farma – A Precision for Medicine Company

Biotech and pharma innovators struggle to cost-effectively manufacture personalized treatments at commercial scale. Complex therapies like cell and gene treatments remain prohibitively expensive, limiting access. Manual, artisanal production processes also constrain capacity and prevent broader availability of potentially curative options for patients in need.

-

Manufacturing - Gene Therapies - Clinical Trials

Next in Gene Therapy: Trends, Innovations, and Challenges

- |

Drawing on leading-edge case studies, this article outlines optimized approaches to:

- Streamline and automate processes for efficiency and scale

- Implement closed, standardized production systems

- Drive down costs through process intensification innovations

- Access turnkey manufacturing solutions via creative partnerships

By putting these strategies into practice now, experts believe you can achieve the manufacturing agility and flexibility needed to translate groundbreaking science into accessible therapies that improve outcomes for patients globally.