Introduction

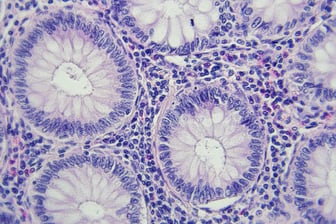

Immunohistochemistry (IHC) is a cornerstone technique in both research and diagnostic laboratories, playing a vital role in identifying biomarkers within tissue samples. For researchers seeking to validate IHC assays, navigating the regulatory landscape is often complex. This article discusses critical aspects of assay development, regulatory pathways, and practical steps for successful clinical trials and assay commercialization.

Importance of validation for IHC assays

Validation ensures that an IHC assay is reliable and reproducible for biomarker detection in clinical settings. The purpose of an assay directly correlates with the level of validation required. Assays designed for research purposes require less robust validation than those meant for informing patient care treatment decisions. The intended use, sample collection region, and patient risk determine the regulatory strategy, which in turn informs the laboratory strategy for IHC assay development and validation.

Figure 1. Assay use and associated validation

Is CLIA validation enough?

The Clinical Laboratory Improvements Amendment (CLIA) regulation applies broadly to any laboratory test but does not define how to satisfy each performance study required. Precision for Medicine bases its IHC assay validation recommendations on additional publications, guidance specific to analytical validation of IHC assays, historical Center for Devices and Radiological Health (CDRH) approvals, and FDA feedback.

Figure 2. Precision for Medicine recommended IHC CLIA validation

Figure 2. Precision for Medicine recommended IHC CLIA validation

Pre-market approval (PMA) submissions will require studies that exceed CLIA requirements. The Clinical Laboratory Standards Institute (CLSI) guidelines provide recommendations on study designs, requirements, statistical methods, and acceptance criteria for evaluating all aspects of an assay for commercialization. Notably, the analytical validation varies among technologies, so the requirements for IHC-based assays are different than for next generation sequencing (NGS)-based assays. Since it is not always clear how to apply the CLSI guidelines to every assay and scientific methodology, the FDA suggests a pre-submission meeting to align on the appropriate designs for analytical validation study prior to conducting them.

Another important consideration in the analytical validation strategy is a single site in vitro diagnostic (IVD) versus an IVD kit. There will be a smaller analytical validation data package for single site IVDs due to the lack of a multi-site reproducibility requirement.

Regulatory strategy development

Significant risk and nonsignificant risk assessment for IVDs

Risk evaluation is based on how the device is used in the investigational therapeutic study (see Figure 3). When the assay is not used to make treatment determination, an investigational device exemption (IDE) is generally not required, unless the sample is obtained through a high-risk procedure.

Figure 3. Risk assessment for IVDs

Figure 3. Risk assessment for IVDs

When an assay is used for prospective stratification or clinical decision-making, it is necessary to perform a study risk determination (SRD) to evaluate if an IDE is required.

Figure 4. IVD assay regulatory submission strategy algorithm

Figure 4. IVD assay regulatory submission strategy algorithm

Manufacturers have the option of submitting an SRD Q-submission to the FDA and having the Agency determine whether the assay use for that protocol represents a significant risk. Alternatively, risk could be assessed by the institutional review board (IRB) as a surrogate for the FDA or a risk assessment could be included in the pre-investigational new drug (IND) briefing book. In some cases, manufacturers may choose to simply assume significant risk and submit an IDE.

Regardless of the option chosen, the FDA is the ultimate arbiter of significant risk. Keep in mind that SRD is irrespective of the phase of the trial and that risk assessment is independent of IND submission and approval.

Figure 5. Pro forma timeline for IHC clinical trial assay development and testing.

Figure 5. Pro forma timeline for IHC clinical trial assay development and testing.

Data from the phase 1 study is used to select a clinical cutoff. CLIA validation is designed around that cutoff to use the assay for inclusion/exclusion in the phase 2 study. Risk assessment is performed concurrently with CLIA validation, and an SRB Q-submission is submitted to the FDA. If the result of the FDA assessment is NSR, the phase 2 study can begin. However, if the agency provides an SR determination, an IDE is developed using the CLIA validation to submit a package to the FDA.

Comparison of US versus EU requirements

There are distinct differences between the US and European Union (EU) regulatory frameworks for IVDs (see Figure 6).

Figure 6. US vs EU comparison for IVD assays

Figure 6. US vs EU comparison for IVD assays

The EU framework centers around the medical purpose of the assay and risk assessment based on the assay use. A key difference between the US and EU systems is the classification of a companion diagnostic (CDx). In the US, CDx may be classified as either Class II or Class III devices. In the EU, they are uniformly classified as Class C devices under the In Vitro Diagnostic Regulation (IVDR). The regulatory authority in the EU is the notified body, whereas in the US, it is the FDA.

If the assay has a medical purpose in a clinical trial, it requires an Annex XIV submission to the national competent authority and ethics committee approval prior to use in the clinical trial in each EU country where samples are being collected for testing. This requirement for country-specific submissions often adds complexity to the regulatory landscape due to local country requirements and the method of submission, ranging from electronic portals to traditional mail or even hand-delivered documents.

-

Translational Research - Biomarkers - Assays - Immunohistochemistry (IHC)

Immunohistochemistry in Precision Medicine: From Biomarker to Clinical Trial Assay

- |

Developing a global validation strategy

To successfully commercialize an IHC assay in both the US and EU, manufacturers must plan parallel validation strategies. Precision for Medicine is well-equipped to handle both CLIA and IVDR requirements, ensuring that assays can be validated for use across multiple regulatory jurisdictions. Validation studies performed in US-based laboratories can be designed to meet both CLIA and CLSI standards while simultaneously supporting EU regulatory submissions under ISO 13485 and good clinical laboratory practice (GCLP) guidelines. By building a comprehensive validation package from the outset, manufacturers can avoid duplicating efforts, thus streamlining the regulatory process.

Figure 7. US vs EU assay validation requirements

Commercializing a CDx

For CDx commercialization in the US, the FDA favors a modular PMA process. Each module is reviewed independently and must be approved before submitting the next module. It is important to align with the FDA on PMA Shell Content prior to submitting the first module via Q-submission. The overall timeline for review is approximately 12 to 24 months. Compliance with 21 CFR Part 820 and Bioresearch Monitoring (BIMO) audit of the facility are required prior to approval.

In the EU, the process follows a different timeline, with an estimated 12 to 18 months required for CE marking under IVDR. The approval process for a CDx requires a technical dossier, including both analytical and clinical data, consultation with a competent authority or the EMA, and audit of the QMS by a notified body.

Key regulations and standards

Key regulatory standards and guidelines for IHC assay validation include:

- CLIA. regulations include federal standards applicable to all U.S. facilities or sites that test human specimens for health assessment or to diagnose, prevent, or treat disease.

- CLSI. This not-for-profit organization develops laboratory standards worldwide. CLSI Guidelines are recognized by laboratories, accreditors, and government agencies as the best way to improve medical laboratory testing.

- IVDR. This is the current regulatory basis for placing on the market, making available, and putting into service IVD medical devices on the EU market.

- 21 CFR Part 820. This regulation defines quality system requirements for medical devices. This framework, which includes good manufacturing practices (GMP), is essential when developing assays intended for commercial use in the U.S. Effective February 2, 2026, the FDA is implementing the Quality Management System Regulation, which merges 21 CFR Part 820 with the international standard ISO 13485.

- ISO 14971. The processes described in this standard are intended to help manufacturers to identify the hazards associated with a medical device; to estimate, evaluate and control those risks; and to monitor the effectiveness of the controls.

- ISO 15189. This standard specifies requirements for quality and competence in medical laboratories.

- ISO 13485. This international standard outlines requirements for a quality management system (QMS) for the medical device industry and its imminent integration into FDA regulations marks a shift toward more globally harmonized standards.

Key takeaway

Navigating the regulatory landscape for IHC assay development and validation is complex but critical. By understanding the differences between US and EU requirements and aligning validation strategies accordingly, manufacturers can ensure the success of their assays in both markets. At Precision for Medicine, our expertise in both regulatory and laboratory strategy offers a resource for companies to streamline the process of IHC assay development, validation, and commercialization. Our IVD regulatory team has vast experience, with over 200 submissions for IVD and CDx, including Q-submissions, IDE applications, and Annex XIV submissions, as well as over 250 510(k), EUA, de novo, and PMA submissions for both IVD and CDX in the U.S.

Learn more about Precision's IVD and CDx regulatory affairs consulting services>

We also recommend:

Watch our on-demand webinar to learn about the benefits of using IHC for target and biomarker validation, and understand its multifaceted applications in disease screening and decision-making for treatment.